Cold Chain Management Websites are platforms designed to oversee and manage the storage, transportation, and handling of temperature-sensitive products. These websites integrate various technologies and tools for real-time monitoring, data logging, and reporting. This helps track the condition of products, manage inventory, schedule deliveries, and ensure regulatory compliance.

Notwithstanding, through the Chillventa Congress, you can get unlimited professional expertise at its finest in supporting programs and its unique presentations. You will get to meet and create business contacts face-to-face with professionals you can engage with. Also, discover a few cold chain management websites to partner with. The day before the exhibition event is an icing on the cake.

Usually, this is when high-caliber speakers share their knowledge from the R&D, industrial, and political arenas. It’s where you will learn firsthand how the industry’s future is evolving and have the opportunity for in-depth professional discussions. Back on October 10, 2022, the main themes of the congress explored four different streams. They included Heat Pump Technologies (English).

In addition, there was also Innovation Day Refrigeration Technology (German), Data Centres (German), and the ASERCOM-EPEE Symposium (English). The symposium provides information about current policy frameworks and regulations worldwide. With that in mind, learn why acquiring more knowledge on designing a user-friendly interface for a cold chain management website is essential.

Learn What Cold Chain Management Websites Offer In Cloud Computing Sectors

Technically, the cold chain management process is an essential component of the supply chain, integral to maintaining temperature ranges and air quality, including carbon dioxide, humidity, and oxygen levels. Note: Any disruption or failure within the cold chain management process during transit, processing, storage, and display may result in product spoilage, loss, and financial implications.

In other words, a cold chain is an uninterrupted flow of a specific thermal profile throughout a temperature-sensitive product’s manufacturing, packaging, and distribution. As a rule of thumb, maintaining the correct temperature and product environment is a critical success factor in the supply chain for everyone involved — from product manufacturers and shippers to the end customers.

As mentioned, gathering more knowledge and skills to upgrade your experience matters. This is due to the complex nature of cold chain logistics, and the critical importance of precise temperature control means that the website should be intuitive and easy to use. The aim is to create successful cold chain websites to improve customer retention while addressing features like functionality.

So, to summarize, cold chain management websites are digital applications or online platforms that help manage all phases of the cold chain. This may often include products in transit, processing, storage, and display. For instance, temperature-sensitive products and goods rely on cold chain management for product efficacy, product safety, and adherence to relevant regulatory requirements.

The Notable Cold Chain Management Processes That Empower Businesses

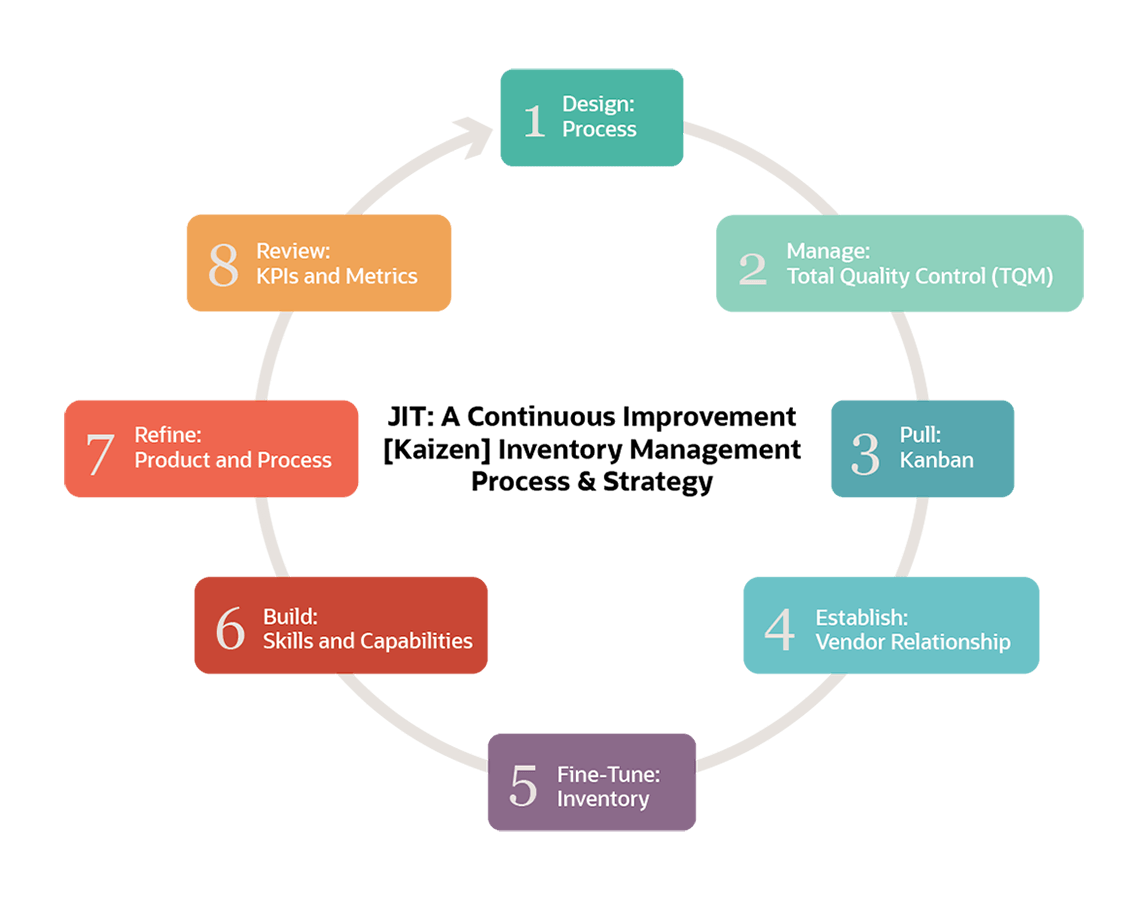

Usually, some cold chain management services, such as Just In Time (JIT), often ensures the delivery of thermal packaging supplies. Coupled with cold chain best practices in GAP analysis, such tools ensure you and your customers benefit from an efficient, streamlined, cost-effective cold supply chain. On the one hand, a solid cold chain management process includes storage factors.

On the other hand, some tools help in packaging, tracking, transportation, customs clearance, product management, and delivery of products safely and securely. The cold chain management process heavily relies on innovative AI Analytics technology. This helps to monitor and maintain the temperature, logistics, movement, delivery, and security of temperature-sensitive products and goods.

Moving goods and products across the country and waterways is not simple. It’s costly, time-consuming, and can be inefficient. Fortunately, cold chain management uses integrated intelligent Internet of Things (IoT) and cloud-enabled tracking and monitoring. Thus, companies can streamline their products’ transport, delivery, and storage – helping to improve efficiencies and reduce costs.

The cold supply chain is a temperature-controlled and temperature-sensitive supply chain. Thus, the process is integral to the safe manufacturing, packaging, transporting, monitoring, and delivering a wide range of products and goods. However, it’s necessary to ensure compliance with regulations governing safe production, transport, delivery, and temperature-sensitive product storage.

The Cold Chain Roles:

- Management Logistics: Maintaining the cold chain requires more profound and broader planning and management. For example, temperature-sensitive products cannot be left unattended in a delivery yard or waiting at customs clearance.

- Specialized Equipment: Reefers, vaccine freezers, refrigerators, insulated pallets/containers, temperature, and data trackers—this equipment is standard practice for maintaining and supporting the cold chain.

- Public Health Risks: When vaccines or food are not kept in temperature-controlled environments, the risks to public health are high. The cold chain is imperative to public health and safety, from food poisoning and food insecurity to unsafe vaccines and the risks of disease spread due to vaccine unavailability.

- Data Documentation: Some regulation standards and compliance practices translate to extra paperwork and document verification. The regular supply chain brings plenty of documentation. At the same time, the additional regulatory standards from the FDA, DOT, CDC, WHO, EU, and others mean the cold chain has additional documentation requirements.

Remember, a well-crafted UX design anticipates the user’s needs and creates a seamless flow. This reduces friction and enhances satisfaction. At the same time, responsive website design contributes to the website’s search engine ranking, as mobile-friendliness is a ranking factor. With cold chain management, products are monitored and tracked throughout every step of the cold supply chain.

The Key Processes:

- Products Storage: Insulated containers, vaccine and medical refrigerators and freezers, refrigerants, and cold rooms/chillers are essential to adequate cold storage. Cold chain management starts with cold chain storage equipment and facilities.

- Goods Packaging: When products leave storage facilities, cold packaging is vital to maintaining and monitoring temperature and security. Products such as cold chain parcel and pallet systems, refrigerant bricks, gel packs, gel bottles, and insulated containers and envelopes keep your products cold, improve transportation efficiencies, and prevent damage, waste, and loss.

- Performance Tracking: Usually, data loggers and temperature indicators give companies, shippers, and their customers real-time temperature and GPS monitoring and tracking. This information is critical to maintaining the cold chain and ensuring product quality and integrity.

- Product Transportation: The global supply chain means temperature-sensitive goods and products are moved worldwide in various ways. Specialized cold chain vehicles such as refrigerated vehicles and reefer containers keep the cold supply chain moving across waterways, air, and global/local roads and highways.

- Customs Clearance: Customs paperwork is vital in the cold supply chain, ensuring products can be transported and delivered quickly and efficiently. Failure to comply with customs clearance requirements can result in delays – causing product loss, product quality risks, and additional storage, transport, and delivery expenses.

- Products Management: Shipping supplies such as specialized cold parcels and pallets, insulated envelopes and containers, and warehouse best practices with autonomous mobile robots and forklifts mean your products are moved and handled securely and safely within the cold chain.

- Goods Delivery: Ultimately, delivering temperature-sensitive products and goods to your B2B and B2C customers depends on a finely tuned and streamlined delivery process. The cold chain management process includes documentation review, internal handling best practices, risk management, and securing compliant warehouse, storage, and display systems.

The above mentions are just a few of the crucial processes. With that in mind, you can sign up for cold chain technology blog updates to learn the latest about supply chain management, new tools, and innovative cold chain technologies. In addition, you can also find out how the Cold Chain Tech Team can help you maintain the integrity, safety, and quality of your temperature-sensitive products.

Steps To Design Cold Chain Management Websites User-Friendly Interfaces

With the help of a professional team, cold chain management websites may help keep you out of the news headlines for the wrong reasons. Of course, no one wants to be making headlines for unsafe user products and goods. Effective temperature control and monitoring means your standards and regulatory standards are met—this helps keep your content safe and customers happy.

Eventually, the history of cold chain management dates back to 1797. This was a time when British fishers used ice to preserve their catch. In 1938, American inventor Frederick Jones developed the first portable air-cooling unit for vehicles transporting perishable food. During World War II, these units were integral to the secure transportation, preservation, and blood/medicine/food safety.

It also came in handy for the resources used at military hospitals and on the battlefield. The growth of the cold chain industry is linked to the Interstate Highway Act of 1956. Think of the cold chain as a temperature-controlled supply chain. A successful cold chain requires an unbroken and stable chain of refrigerated manufacture, production, packaging, transport, storage, and distribution.

For example, as an online marketplace business trader or a digital storefront owner, your customers expect your products to arrive without bruising, discoloration, textural changes, bacterial growth, or worse. This is an integral service solution that most cold chain management websites offer you and your potential customers. On that note, below are the steps for novice design webmasters.

1. Understand Your Audience

First, cold chain management websites often focus on a design with a user-friendly interface—begin by thoroughly researching your target users. Remember, your users are typically logistics, warehousing, and cold chain operations professionals. Secondly, it’s crucial to understand their daily challenges, the type of information they frequently need, and how they interact with technology. Consider factors such as their technical proficiency, the urgency of their tasks, and their preferences for data presentation. This understanding will guide the design and functionality of the website. It also ensures the website is tailored to meet their needs and preferences.

2. Simplify Navigation Process

Simplified navigation is vital for cold chain management websites. Users should find what they need quickly and effortlessly, whether it’s shipment details, cold chain inventory levels, or temperature records. Organize the content logically with clear labels and a hierarchical structure to mirror the users’ thought processes. Include search functionality and filters to help users quickly locate specific information. Asking actual users to test the navigation can also help identify and fix any points of confusion or inefficiency.

3. Responsive Website Design

Users might access the cold chain management websites and applications in various settings. For instance, they may access the application on the go, so having a Responsive Web Design (RWD) in place is essential. Webmasters aim to ensure that the website adapts seamlessly to screen sizes and resolutions, from desktop monitors to smartphones and tablets. Furthermore, a responsive design ensures all functionalities are accessible and usable across devices to maintain consistent performance and user experience.

4. Analyze Real-Time Data

Access to real-time data is critical. Users must have real-time data access for decision-making and maintaining product integrity. As such, your website should offer real-time tracking features for shipments, temperature monitoring, and inventory levels. Ensure the data is presented in an easily digestible format. Consider implementing alerts or notifications for critical situations, such as temperature deviations. This capability enhances operational efficiency and builds trust and reliability among customers.

5. Utilize Data Visualization

In layman’s language, effective data visualization in cold chain management websites is critical to understandably presenting complex information. In that case, you can use graphs, infographics, charts, and interactive elements to display temperature trends, shipment tracking, or inventory status. Good visualization helps users quickly grasp the insights from large datasets and make informed decisions. It’s also essential to offer customization options. This allows users to view data in the format that best suits their needs.

6. User Experience And Interface

It’s important to realize that the User Interface (UI) and User Experience (UX) design are integral to creating a visually appealing and functionally efficient website. Realistically, the UI focuses on the website’s layout, design elements, and interactive components. It should be intuitively structured, with a clean and professional appearance. This is simply because it helps website users easily navigate and perform tasks. On the other hand, UX design pertains to the overall feel and experience of using the website. It covers a user’s journey, from logging in to completing specific tasks like monitoring temperatures or managing shipments.

7. Customize User Dashboards

A strategic brand style personalization plan can significantly enhance user experience regarding cold chain management websites. Allow users to customize their dashboards to display the information most relevant to their roles and needs. Usually, the UI/UX design customization process can include thematic layout changes, choosing which content to display, and setting up personalized alerts or reports. As a result, this flexibility ensures users can optimize the website for their specific workflow and preferences.

8. Add Feedback Mechanisms

In this case, don’t forget to incorporate a straightforward and accessible feedback mechanism when designing a website. Encourage users to share their experiences, suggestions, and concerns. This feedback is invaluable for identifying areas for improvement. One thing is sure: It helps website designers understand user needs and stay aligned with industry trends and changes. At all costs, regularly reviewing and acting on user feedback demonstrates a commitment to user satisfaction and continuous improvement. Still, regular customer feedback and user engagement can provide valuable insights for continuous improvement.

9. Integrate Safety Measures

Goods and products’ safety, integrity, quality, and application useability depend on an effective plan fostered by cold chain management websites. Modern cold chain management using the latest thermal packaging, temperature tracking and monitoring, and storage ensures temperature-sensitive products’ safety, quality, and integrity. From keeping milk cold, ice cream frozen, or vaccines protected—cold chain management and logistics help keep the supply chain of vital goods and products operating smoothly.

10. Manage Damage Control

Product waste, damage, and loss are among the most significant supply chain challenges. Thus, optimizing cold chain management websites through a continuous regression testing process in a monitoring strategy is invaluable. Generally speaking, 24/7 testing/monitoring of temperature, humidity levels, air quality, GPS location, energy use, delivery, and storage conditions are vital aspects of modern cold chain management. Furthermore, with the tight margins and supply chain stressors, no company can afford the financial or reputational damage that comes with the trickle-down impacts of ruined temperature-sensitive products.

The Bottom Line:

As you can see, cold chain management websites are essential application platforms for webmasters and cloud-based businesses to efficiently track, monitor, and manage temperature-sensitive user goods and materials. You now know how to create compelling and user-friendly websites. Users can trust your website to manage their cold chain operations with these features reliably.

In a nutshell, it’s worth mentioning that some essential products requiring cold chain solutions include pharmaceuticals, vaccines, biologics, lab samples, diagnostic materials, chemicals, food, and beverages. Maintaining the cold chain demands knowledge and control of the shipping environment, package design, duration of the shipment(s), and critical control points throughout the process.

Markedly, your B2B and B2C customers want your products and goods. However, they expect these products to arrive on time and adhere to high levels of quality and safety. By all means, most cold chain management websites and logistic platforms offer you the correct insights and control over the distribution, storage, and delivery processes. This helps to meet your customer expectations.

Still, with the tight margins and supply chain stressors, no company can afford the financial or reputational damage that comes with the trickle-down impacts. Companies depend on advanced thermal packaging, sophisticated refrigerants, reefers, cold chain parcel and pallet systems, temperature monitoring, and specialized insulated containers to protect and secure their goods and products.

Get Free Updates

Notice: All content on this website including text, graphics, images, and other material is intended for general information only. Thus, this content does not apply to any specific context or condition. It is not a substitute for any licensed professional work. Be that as it may, please feel free to collaborate with us through blog posting or link placement partnership to showcase brand, business, or product.