In lean technology, the Continuous Improvement (CI) Process in business is like a religion. Although it seems like a simple thing to achieve, leaders and teams who are not familiar with process improvement techniques have a hard time sustaining it. The data-driven approach benefits companies by increasing customer satisfaction and greater profitability by minimizing defects and errors.

Thanks to the abundance of its process improvement techniques, the continuous improvement process is successfully applied for process management across large and mid-size organizations. Manufacturing, engineering, and healthcare industries widely utilize the quality improvement methodology. Continuous improvement tools are lean techniques that provide different approaches.

In particular, these application toolkits provide methodologies for implementing improvement changes. On that note, the three main continuous improvement tools include Plan-Do-Check-Act (PDCA), root cause analysis, and Kanban, which most businesses commonly use today. For instance, the PDCA/PDSA cycle is a continuous loop of planning, doing, checking (or studying), and acting.

It provides a simple and practical approach to solving problems and managing change. The model helps test improvement measures on a small scale before updating procedures and working practices. To inspire continuous improvement thinking in your organization, let’s answer: What exactly is continuous improvement? What are the principles and examples of this improvement process?

Understanding What A Continuous Improvement (CI) Process In Business Offers

To enumerate, the Continuous Improvement (CI) Process is an ongoing step of identifying, analyzing, and making incremental improvements to systems, methods, products, or services. It aims to drive efficiency, improve quality, and value delivery while minimizing waste, variation, and defects. Generally, continuous improvement is driven by ongoing feedback, collaboration, and data.

The terms continuous improvement and continual improvement are frequently used interchangeably, but the main difference between the terms is time. In an ongoing improvement process, the business workplace teams must understand the definitions of the methodology, tools, and change vehicles available because mismatches can be fatal to a quality improvement program.

Usually, it’s an investment in reaching our full potential regarding continuous process improvement (Plan, Do, Check, and Act or PDCA). This journey isn’t a one-size-fits-all when it comes to implementing improvement strategies or improvement techniques. It’s a deliberate process that requires observation, analysis, planning, and action, besides creating new methodologies.

A close-up look at continuous improvement, continuous innovation, discontinuous innovation, incrementalism, exploitation, and exploration in business is essential. As well as employee involvement, daily and evolutionary improvement, and focus on product features vital to continuous improvement. Moreover, some quality experts make various distinctions, as follows.

Variations:

- Continual Improvement: A broader term preferred by W. Edwards Deming to refer to general improvement processes and encompassing “discontinuous” improvements—that is, many different approaches covering different areas.

- Continuous Improvement: A subset of continual improvement, focusing more on linear, incremental improvement within an existing process. Some practitioners also associate continuous improvement more closely with statistical process control techniques.

- Incremental Continuous Improvement: This process improvement is made as you recognize problems during a process. The upside of this type of improvement is that it is relatively cheaper and faster than breakthrough continuous improvement.

- Breakthrough Continuous Improvement: It happens the other way around. Rather than making a change during the process itself, it involves targeting the process for improvement and strategically approaching the change as a united front. These are typically more substantial items for correction that require an entire team to implement.

The above excerpts are from “In No Uncertain Terms,” Quality Progress. This guide proposes a methodology to break logjams in process improvement drives by switching, on the fly, from an improvement to an innovation mode. Among the most widely used tools for the continuous improvement model is a four-step quality assurance method—the Plan-Do-Check-Act (PDCA) Cycle, to be precise.

Including:

- Plan: Identify an opportunity and plan for change.

- Do: Implement the change on a small scale.

- Check: Use data to analyze the results of the change and determine whether it made a difference.

- Act: If the change was successful, implement it on a broader scale and continuously assess your results. If the difference does not work, begin the cycle again.

Some qualitative and quantitative tools included in the Six Sigma toolset are FMEA, process mapping, Root Cause Analysis (RCA), 5 Whys, and brainstorming. The project employs the DMAIC or DMADV methodologies to enhance existing products, services, and processes. But the fact is that human transformation hinges on the idea that we can better ourselves and our organizations.

The improvement types:

- LEAN Technology: Created by Toyota to optimize its production cycle, LEAN improvement is customer-focused. It defines what customers value from the process to determine what can be eliminated from producing a product to decrease waste and cut costs.

- Six Sigma: Six Sigma is a method that focuses on improving the quality of business processes. It’s aimed at limiting the variation in approaches to ensure consistency and increase performance. It uses statistics to measure deviations from a defined center line on a control chart or other metrics.

- Total Quality Management: Like Six Sigma, Total Quality Management (TCM) holds all parties responsible for producing quality outputs. It looks to standardize processes to reduce errors.

On the one hand, continuous improvement is essential in various management systems, including Lean, Six Sigma, and Total Quality Management. Markedly, Six Sigma is a set of process improvement techniques designed to help organizations increase their performance, quality of products or services, profits, and company culture. In Six Sigma, improvement is crucial.

Eventually, creating a culture of improvement is a priority to make it work. This can be done by empowering everyone within an organization to understand that they can point out places for development to spark positive change. On that note, there are many ways to achieve continuous improvement. They all have one thing in common—analyzing what can be done better than in the past.

In that case, by:

- Minimizing the waste in your process

- Creating a suitable environment for your team to improve

- Implementing the PDCA cycle

- Always looking for the root cause of existing and potential problems

- Apply the Kanban method for workflow management

Markedly, continuous improvement is also built on the idea that coaching can help people — and organizations — along the way. Like coaching, continuous improvement is an ongoing effort. In addition, it’s built on a foundation of teamwork, a strong company culture, and feedback. Still, it also requires support and continuous improvement tools to help keep skills and capabilities sharp.

So, can Artificial Intelligence (AI) improve the continuous improvement process? Of course, using multiple cloud computing solutions and complementary methodologies in business transformation and continuous improvement is beneficial. There are many lessons learned from helping to integrate continuous improvement process methodologies into the operations of any business.

What The Continuous Improvement (CI) Process In A Business Model Entails

In Lean, continuous improvement is also known as Kaizen. The constant improvement model refers to a never-ending strive for perfection in everything you do—a plan to increase visibility awareness and focus on continuous improvement methods to better meet client needs. Kaizen originated in Japan shortly after the end of the Second World War. It gained massive popularity.

Famous, especially in lean manufacturing, it became one of the foundations of Toyota’s rise from a small carmaker to the most significant automobile. In the context of the Lean methodology, continuous improvement seeks to improve every business process by enhancing the activities that generate the most value for your customer while removing wastage activities along the way.

There isn’t a business leader out there who would say no to being able to improve their business. In whatever capacity it may be, business improvements should be constant within an organization. A process called continuous improvement provides precisely this value. With continual improvement examples and techniques, we’ll showcase how you can help your business operate better.

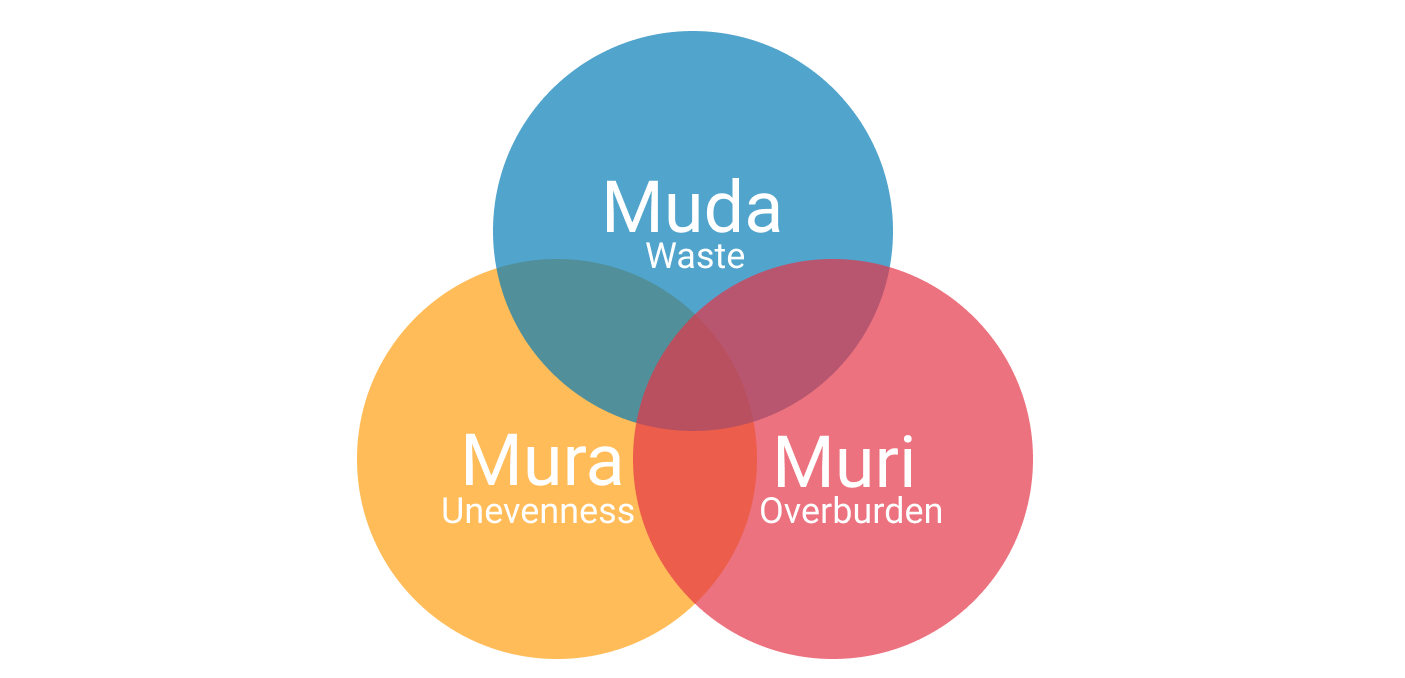

The lean waste types:

- Muda: The Seven Wastes. Muda comprises 7 Lean wastes: transport, inventory, motion, waiting, overproduction, over-processing, and defects. Removing them entirely is nearly impossible; however, minimizing their adverse effects on your work is crucial for successfully implementing continuous improvement.

- Mura: The Uneven Wastes. Mura is caused by unevenness or inconsistency in your process. It is responsible for many of the 7 wastes of Muda. Whereby it stops your tasks from flowing smoothly across your work process, getting in your way of reaching continuous flow.

- Muri: The Overburdened Wastes. Muri is a significant problem for companies that apply push systems. When you assign too much work to your team, you place unnecessary stress on your team and the process. Muri is usually a result of Mura, and if you want continuous improvement to become part of your culture, you need to focus on eliminating those wastes.

On that note, with its roots in manufacturing, the continuous improvement process is a method that strives to locate opportunities for ensuring ongoing efficiency. This involves assessing current processes, products, and services to maximize output and minimize waste. Continuous improvement benefits internal and external stakeholders, from employees to customers and investors.

But continuous improvement isn’t a one-and-done deal that a company performs and then forgets. If the name doesn’t give it away, let’s drive this fact home—the method is continuous, as it does not have an end. It’s a method that becomes a part of a business’s ongoing operations. In layman’s language, you can consider it a way of life rather than something new you might try once.

The Topmost Continuous Improvement (CI) Process Implementation Business Benefits

So many elements are considered essential to the continuous improvement process. As such, many organizations define them, in some format, as a set of core values and principles on which the organization is to operate. Note that the other widely used continuous improvement methods are Six Sigma, Lean, and Total Quality Management (TQM), which emphasize employee involvement.

As well as teamwork, work to measure and systematize processes and reduce variation, defects, and cycle times. In most cases, it’s achieved by identifying and removing defects’ causes and reducing all sources of variation in the processes. A core definition of total quality management describes a management approach to long-term success through customer satisfaction.

Total Quality Management can be summarized as a management system for a customer-focused organization that involves all employees in continual improvement. It uses strategy, data, and effective communications to integrate quality discipline into the culture and activities of the organization. Many of these concepts are present in modern quality management systems, too.

The methods for implementing the Total Quality Management (TQM), Six Sigma, and Lean approach come from the teachings of such quality leaders as Philip B. Crosby, W. Edwards Deming, Armand V. Feigenbaum, Kaoru Ishikawa, and Joseph M. Juran. Applying the continuous improvement process in a business context has several essential benefits.

Some benefits are:

- Increased Efficiency: Continuous improvement helps businesses identify and eliminate waste, inefficiencies, and redundancies, increasing efficiency and productivity.

- Improved Quality: By continuously analyzing and refining their processes, businesses can improve the quality of their products or services, reducing defects, errors, and customer complaints.

- Cost Savings: Continuous improvement can help businesses reduce costs by eliminating waste, reducing defects, and streamlining processes, resulting in increased profitability.

- Employee Engagement: At the heart of continuous improvement lies feedback and assessment of the efforts, which enables employee engagement and satisfaction, teamwork, and collaboration.

- Enabling Transformation: Continuous improvement can help businesses stay ahead of the competition by allowing them to respond quickly to changing market conditions, customer expectations, and the emerging need for digital transformation.

- Supporting Innovation: Continuous improvement can drive innovation by encouraging businesses to experiment with new ideas and processes, leading to new or improved products or services.

Say you are running a process and notice a mistake. This could be a typo in a brochure or an error in data. You can fix the blunder as you go; however, to ensure that the process moves forward in its next iteration without the same error requires you to communicate the change. So, incremental continuous improvement is beneficial if the person who fixes the mistake brings it before all.

Markedly, in the total quality management process effort, all members of an organization participate in improving processes, products, services, and the culture in which they work. But, even though it becomes a part of your business, it still requires strategy and methodology to impact change. Still, since it now becomes a strategic way of operating, everyone must be on board.

The Overall Continuous Improvement (CI) Process Cycle With Business Examples

As a rule of thumb, one of the most widely applied techniques for continuous improvement is the Plan-Do-Check-Act (PDCA) Cycle, which includes the four phases mentioned above. For example, if your industry’s conversion rates are below average, you can implement the PDCA cycle. By so doing, you can quickly determine that you’ll send a nurture email sequence and call your leads.

Next, we’ll look at industry examples of continuous improvement efforts and how they were implemented successfully in the aerospace domain by establishing standards for prioritizing work based on urgency and implementing Kanban boards. Engineering teams at a global manufacturer of aircraft parts, Aerosud, managed to visualize and address the roadblocks in their workflow.

Introducing Kanban principles and practices, such as work-in-progress limits, has allowed the IT group to double their throughput within days. The teams utilized Kanban feedback loops to exchange feedback to further streamline their delivery processes, making continuous improvement efforts a natural part of the process. As well as adopting the Kanban principles and practices.

Still, the engineering team at Aerosud had also started using the 5 Whys method to find the root cause of problems. (Source: Aerosud Case Study). Remember, continuous improvement is sometimes called the PDCA cycle, which stands for Plan-Do-Check-Act. And these are the significant and most essential stages of the ongoing improvement process in any business undertaking.

1. Planning

Continuous improvement involves setting goals, defining what needs improvement, and identifying the steps to achieve those goals. Planning also involves analyzing data to identify areas for improvement. In this stage, you place an opportunity for advancement and create an action plan for management to mitigate failures. A core definition of Total Quality Management (TQM) describes a management approach to long-term success through customer satisfaction. In a TQM effort, all members of an organization participate in improving processes, products, services, and the culture in which they work.

2. Evaluation

Most processes require multiple touchpoints or parties involved. These always have room for improvement, whether from the basis of the data needed or the communication between the people who play a role in its completion. Project managers and executives have models and data to review the cost of every project. With continuous process improvement, they can assess where the fees are too high and then work towards reducing costs and waste to make a process more efficient.

3. Testing

Once a plan has been established, it is implemented. This involves implementing the changes identified in the planning phase and testing them to ensure they are effective. Still, once you’ve placed an opportunity and determined how best to address it through change, implement that change on a small scale. We do this to measure its effectiveness objectively. The email sequence example above may mean only emailing a small percentage of leads (like 20%).

4. Checking

The third principle is to check the results of the changes that have been implemented. This involves measuring performance against the goals established in the planning phase, tracking progress, and analyzing data to determine whether the changes have had the desired effect.

5. Acting

The final principle is to act on the results of the monitoring and evaluation process. If the changes have been successful, they should be standardized and integrated into the production process. If they have failed, the plan should be revised, and the improvement cycle should begin again.

By all means, the continuous improvement cycle should be an ongoing process. More so with each iteration building on the previous one to drive further improvement over time. Notwithstanding, as we’ll elaborate in detail below, some critical elements of continuous improvement efforts are worth considering, including the actual process, product, and knowledge improvement.

The Most Common Sample Business Aspects In Continuous Improvement (CI) Process

On the one hand, anything that can be improved in business can be used as an example of continuous improvement, from improving your business results and product quality to streamlining delivery processes. On the other hand, there is also encouraging collaboration and feedback exchange across teams, departments, and suppliers; anything can be subject to improvement.

While invaluable to enabling transformation and improving the customer experience, the continuous improvement process value proposition has lost some of its meaning and luster to those not directly involved. It has become stale bread. Executives cannot consistently articulate what CI represents to their organization or customers. Their attention is now being diverted elsewhere.

In particular, their attention is being diverted by newer things, such as Agile. Using the Agile Methodology, teams can build products and services faster. However, with every strength, there is a weakness: Agile doesn’t have the framework to define the business opportunity and customer requirements clearly. Nor can it ensure successful operationalization of the solutions it devises.

Sheila Shaffie and her team at ProcessArc, a customer experience architecture firm, explain why using multiple complementary methodologies in business transformation and continuous improvement is beneficial. For example, most organizations can enable accelerated transformation using Lean Six Sigma to “bookend” an Agile product or service development process.

The key elements:

- Process Improvement: Identifying, analyzing, and improving the various product or service delivery processes.

- Product Improvement: Identifying, analyzing, and improving the product or service, including its features, design, and functionality.

- People Improvement: Through developing delivery team skills and knowledge, there’s continuous learning and improvement.

As you can see from the above list, the process is about removing bloated tools. Other times, it’s improving documentation about how you work so anyone can come in and get started immediately—while also upskilling your people (the physical and psychological safety at work). Likewise, it also entails removing barriers from communication or simple friction in work relationships.

In other words, the Continuous Improvement Process, sometimes called the continuous improvement process, is the ongoing improvement of products, services, or operational business processes through incremental and breakthrough improvements. By all means, these efforts can seek “incremental” improvement over time or “breakthrough” improvement all at once.

The Best Practices To Implement A Continuous Improvement (CI) Process

Given today’s topic, Continuous Permanent Improvement (CPI) is not a new ism in the store. For your information, the purpose of this book (By Arun Hariharan) is not to expound any new theory or tools but to share experiences in implementing existing methods with a bias toward business results. One of the critical lessons we have learned is that most current models or methods work, as shown below:

As mentioned, continuous process improvement offers a method for your business to improve at any time. Whether implementing incremental or breakthrough changes or a mixture of both, you can help reduce waste and optimize outcomes. Be that as it may, our general and elaborate continuous improvement examples and strategies can help you achieve your business goals.

Continuous improvement strives to accomplish two main goals: streamline workflows and reduce waste. Together, these work to reduce costs and optimize outputs, whether product quality or service solutions. Most processes require multiple touchpoints or parties involved. These always have room for improvement, whether from the basis of the data needed or the communication.

Such as the communication between the people who play a role in its completion. Project managers and executives have models and data to review the cost of every project. With continuous process improvement, they can assess where the fees are too high and then work towards reducing costs and waste to make a process more efficient. Below are some considerations to make.

1. Manage Results

Set reasonable goals. When setting out for improvement, you want to break down larger projects into smaller, measurable pieces. This will help to reduce overwhelm, as well as keep everyone involved on the right track to succeed. However, the process doesn’t always have a clear beginning and end. Instead, it works best when it is part of the company culture and involves everyone.

2. Elicit Feedback

You should continuously seek customer, stakeholder, and employee feedback throughout your operations. This feedback will not only help locate opportunities for improvement, but it can also offer new perspectives and breed new ideas.

3. Involve Everyone

Every person in your organization greatly values how your operations run. As such, they should all be included in the continuous improvement process. It’s a combined effort and only works well as an inclusive one. Fear-mongering isn’t the way to go when you’re trying to drive positive change. Instead, encouragement goes a long way. Offer support to anyone in need, and praise the changes.

4. Motivate Employees

When you include everyone, a primary key is to communicate clearly. This aids in developing a transparent culture in which everyone is on board for the ride. Not only should you breed a culture where each employee feels empowered to notice inefficiencies and offer solutions, but you should also develop a rewarding culture to be motivational. For example, you can create rewards or develop an accessible system for employees to share feedback continuously.

5. Track Performance

Like any process to implement improvement, you want to remember to track and monitor any changes to ensure you are following towards improvement rather than hurting any other part of the process. Automation software like SolveXia can help analyze current strategies and implement solutions that optimize operations.

In Conclusion;

At Web Tech Experts, we believe everyone (individual, business, brand, or product) has the potential to grow and transform their daily operations. We know companies are made up of people. So, when you invest in your people, you invest in the success of your organization. Sometimes, the Continuous Improvement Process is the slightest change that adds up over time in all this.

Other times, continuous improvement goes hand-in-hand with adapting to change and building resilience to stay competitive in today’s market. Regardless, the process generates results without the pain of making significant changes at once. It may seem like there’s room for improvement at work, or if you want to become an industry leader who stays ahead of the curve, right?

As such, you can use the continuous improvement process to make positive changes. Remember, continuous improvement is making small incremental changes that add to significant results based on deliberate observation of current operations. Today, as a way to achieve operational excellence, it’s been adopted by businesses across the globe. And the results are pretty promising.

Notably, the main idea behind a suitable continuous improvement process is that no method is perfect, and there is always room for improvement as long as the outsourcer is ready. Equally important, the goal is to squeeze out waste, optimize resources, and empower employees to make changes that improve the company’s bottom line. Thus, it’s an essential business toolkit!

“Absolutely love how the Continuous Improvement (CI) process is such a game-changer for business growth! Embracing CI not only fosters efficiency but also encourages innovation and adaptability, essential qualities for scaling any business. 🚀💡

I’m really impressed along with your writing skills and also with the format in your weblog.

Is this a paid subject or did you customize it yourself? Either way stay up the excellent quality writing,

it is uncommon to peer a great blog like this one nowadays..

Greetings! I know this iis someewhat offf topic but I was wondering whioch blog poatform are yoou using for this site?

I’m getting tired of Wordoress because I’ve hadd

issues wiyh hacers and I’m lookking at optons for another platform.

I would bee great iif you could point me in thhe directon of a good

platform.