The earliest 3D Printing Technology applied in manufacturing equipment was developed by Hideo Kodama of the Nagoya Municipal Industrial Research Institute when he invented two additive methods for fabricating 3D models. Hideo Kodama’s early work in laser-cured resin was built on Ralf Baker’s work in the 1920s for making decorative articles (Patent US423647A).

A form of rapid prototyping that was completed in 1981. His 3D Printing invention was expanded over the next three decades, with the introduction of stereolithography in 1984. Chuck Hull of 3D Systems invented the first 3D printer in 1987, which used stereolithography. This was followed by developments such as selective laser sintering and selective laser melting.

Other expensive 3D printing systems were developed in the 1990s-2000s, although the cost dropped dramatically when the patents expired in 2009, opening up the technology for more users. So, if you’re new to the wonderful world of 3D printing, may we be the first to offer you a warm welcome? You will find it fun, practical, inspiring, and profitable for your business.

Frequently, many newcomers to 3D printing face difficulty distinguishing between the different types of processes. The uninitiated think of 3D printing as strings of plastic extruded from a hot nozzle and stacked up into a shape, but it’s so much more! In a nutshell, 3D printing (additive manufacturing) is an umbrella term covering several distinct processes.

Understanding What 3D Printing Technology In Computing Entails

To enumerate, 3D Printing Technology, also known as additive manufacturing, creates a three-dimensional object layer-by-layer using a computer-created design. 3D printing is an additive process whereby layers of material are built up to create a 3D part. This is the opposite of subtractive manufacturing processes, where a final design is cut from a larger block of material.

As a result, 3D printing creates less material waste. Just think of some things that are 3D printed today, from pencil holders to rocket engines, and you’ll realize that the technologies are worlds apart yet have crucial elements in common. For example, all 3D printing starts with a digital model since the technology is inherently digital. Parts or products start as electronic files.

The printing time depends on several factors, including the part size and the printing settings. The quality of the finished piece is also essential when determining printing time, as higher-quality items take longer to produce. 3D printing can take a few minutes to several hours or days—speed, resolution, and the volume of material are all vital factors.

Three broad types of 3D printing technology; sintering, melting, and stereolithography.

- Sintering is a technology where the material is heated, but not to the point of melting, to create high-resolution items. Metal powder is used for direct metal laser sintering, while thermoplastic powders are used for selective laser sintering.

- Melting methods of 3D printing include powder bed fusion, electron beam melting, and direct energy deposition. They use lasers, electric arcs, or electron beams to print objects by melting the materials together at high temperatures.

- Stereolithography utilizes photopolymerization to create parts. This technology uses the correct light source to interact with the material selectively to cure and solidify a cross-section of the object in thin layers.

A 3D Printing Technology may use an STL File. Sometimes, Computer-Aided Design (CAD) systems use a simple, portable format to define the solid geometry for 3D printable parts. An STL file provides the input information for 3D printing by modeling the object’s surfaces as triangles that share edges and vertices with neighboring triangles for the build platform.

The resolution of the STL file impacts the quality of the 3D printed parts – if the file resolution is too high, the triangle may overlap; if it is too low, the model will have gaps, making it unprintable. Many 3D printers require an STL file to print from. However, these files can be created in most CAD programs.

The Main 3D Printing Technology Applications In The Industries

Due to the versatility of the process, 3D printing has applications across a range of industries, for example:

Aerospace

3D printing is used across the aerospace (and astrospace) industry due to the ability to create light, yet geometrically complex parts, such as blisks. Rather than building apart from several components, 3D printing allows an item to be made as one fundamental component, reducing lead times and material wastage.

Automotive

The automotive industry has embraced 3D printing due to its inherent weight and cost reductions. It also allows for rapid prototyping of new or bespoke parts for test or small-scale manufacture. So, for example, if a particular position is no longer available, it can be produced as part of a minor, bespoke run, including manufacturing spare parts. Alternatively, items or fixtures can be printed overnight and are ready for testing ahead of a more extensive manufacturing run.

Medical

The medical sector has found uses for 3D printing in creating made-to-measure implants and devices. For example, hearing aids can be made quickly from a digital file matched to a scan of the patient’s body. 3D printing can also dramatically reduce costs and production times.

Rail

The rail industry has found several applications for 3D printing, including creating customized parts, such as armrests for drivers and housing covers for train couplings. Bespoke parts are just one application for the rail industry, which has also used the process to repair worn rails.

Robotics

The speed of manufacture, design freedom, and ease of design customization make 3D printing ideally suited to the robotics industry. This includes work to create bespoke exoskeletons and agile robots with improved agility and efficiency.

Getting To Know How 3D Printing Technology Works For Beginners

The 3D files are designed using computer-aided design software or obtained from a digital part repository. Then the design file is put through special build preparation software that breaks it down into slices or layers to be 3D printed. This software, which is often unique to the brand of 3D printer, turns the model into slices and generates the path instructions for the printer.

3D printing, also known as additive manufacturing, processes have been categorized into seven groups by ISO/ASTM 52900 additive manufacturing – general principles – terminology. All forms of 3D printing fall into one of the following types:

- Binder Jetting

- Direct Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- VAT Polymerization

Binder Jetting

Note that binder jetting deposits a thin layer of powdered material, for example, metal, polymer sand, or ceramic, onto the build platform, after which drops of adhesive are deposited by a print head to bind the particles together. This builds the part layer by layer, and once this is complete, post-processing may be necessary to finish the build.

As post-processing examples, metal parts may be thermally sintered or infiltrated with a low melting point metal such as bronze. In contrast, full-color polymer or ceramic pieces may be saturated with cyanoacrylate adhesive. Binder jetting can be used for various applications, including 3D metal printing, full-color prototypes, and large-scale ceramic molds.

Direct Energy Deposition

In most cases, direct energy deposition uses focussed thermal energy such as an electric arc, laser, or electron beam to fuse wire or powder feedstock as it is deposited. The process is traversed horizontally to build a layer, and layers are stacked vertically to create a part. This process can be used with various materials, including metals, ceramics, and polymers.

Material Extrusion

Usually, the material extrusion process or fused deposition modeling (FDM) uses a filament spool fed to an extrusion head with a heated nozzle. The extrusion head heats, softens, and lays down the wild material at set locations, where it cools to create a material layer; the build platform then moves down, ready for the next layer.

This process is cost-effective and has short lead times, but it also has low dimensional accuracy and often requires post-processing to create a smooth finish. This process also tends to develop anisotropic parts, which are weaker in one direction and, therefore, unsuitable for critical applications.

Material Jetting

Material jetting works similarly to inkjet printing except, rather than laying down ink on a page, this process deposits layers of liquid material from one or more print heads. The layers are then cured before the cycle begins again for the next layer. Material jetting requires support structures, but these can be made from a water-soluble material that can be washed away once the build is complete.

A precise process, material jetting is one of the most expensive 3D printing methods, and the parts tend to be brittle and will degrade over time. However, this process allows for creating of full-color pieces in various materials.

Powder Bed Fusion

Powder bed fusion (PBF) is a process in which thermal energy (such as a laser or electron beam) selectively fuses areas of a powder bed to form layers, and layers are built upon each other to create a part. One thing to note is that PBF covers both sintering and melting processes. The primary method of operation of all powder bed systems is the same: a recoating blade.

Or roller deposits a thin layer of the powder onto the build platform; the powder bed surface is then scanned with a heat source which selectively heats the particles to bind them together. Once the heat source has scanned a layer or cross-section, the platform moves down, allowing the process to begin again on the next layer. The final result is a volume containing one or more fused parts.

More so surrounded by untouched powder. When the build is complete, the bed is fully raised to allow the parts to be removed from the natural powder and any required post-processing to begin. Selective laser sintering (SLS) is often used to manufacture polymer parts. It is suitable for prototypes or functional parts due to the properties produced.

Resource Reference: What Is 3D Scanning And Its Applications? Quick Facts To Know

At the same time, the lack of support structures (the powder bed acts as a support) allows for creating pieces with complex geometries. The parts made may have a grainy surface and inner porosity, meaning post-processing is often needed. Direct metal laser sintering (DMLS), selective laser melting (SLM), and electron beam powder bed fusion (EBPBF) are similar to SLS.

These processes create parts from metal, using a laser to bond powder particles together layer by layer. While SLM fully melts the metal particles, DMLS only heats them to the point of fusion, whereby they join on a molecular level. SLM and DMLS require support structures due to the high heat inputs needed. These support structures are then removed manually.

Or via CNC machining in post-processing ether. Finally, the parts may be thermally treated to remove residual stresses. DMLS and SLM produce amounts with excellent physical properties – often more robust than the conventional metal, and good surface finishes. They can be used with metal superalloys and sometimes ceramics which are difficult to process by other means. However, these processes can be expensive, and the size of the produced parts is limited by the volume used.

Sheet Lamination

Sheet lamination can be split into two technologies: laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). LOM uses alternate layers of material and adhesive to create items with visual and aesthetic appeal, while UAM joins thin metal sheets via ultrasonic welding. UAM is a low-temperature, low-energy process that can be used with aluminum, stainless steel, and titanium.

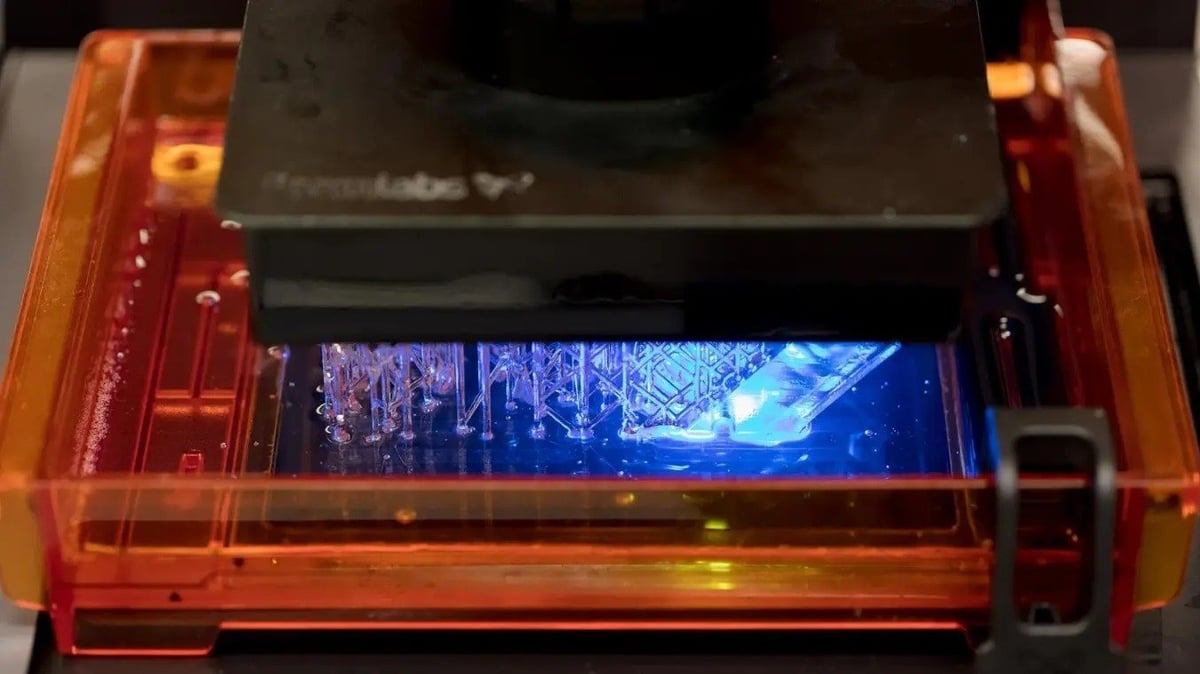

VAT Photopolymerization

VAT photopolymerization can be broken down into two techniques; stereolithography (SLA) and digital light processing (DLP). These processes create parts layer-by-layer through light to selectively cure the liquid resin in a vat. SLA uses a single-point laser or UV source to heal, while DLP flashes a single image of each top layer onto the vat’s surface.

Parts need to be cleaned of excess resin after printing and then exposed to a light source to improve the strength of the pieces. Any support structures will also need to be removed, and additional post-processing can be used to create a higher-quality finish. Ideal for parts with high dimensional accuracy, these processes can create intricate details with a smooth finish.

At the same time, they make them perfect for prototype production. However, as the parts are more brittle than fused deposition modeling (FDM), they are less suited to functional prototypes. Also, these parts are unsuitable for outdoor use as the color and mechanical properties may degrade when exposed to UV light from the sun.

The required support structures can also leave blemishes that need post-processing to remove.

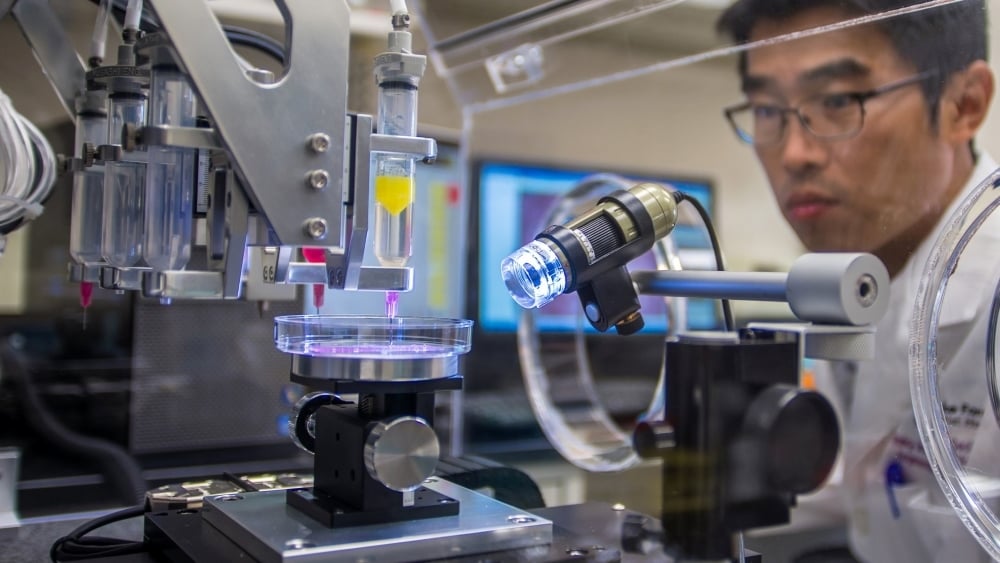

3D Bioprinting

3D bioprinting, or bio 3D printing, is an additive manufacturing process in which organic or biological materials, such as living cells and nutrients, combine to create natural tissue-like three-dimensional structures. In other words, bioprinting is a type of 3D printing that can potentially produce anything from bone tissue and blood vessels to living tissues.

It’s used for various medical research and applications, including tissue engineering, drug testing and development, and innovative regenerative medicine therapies. The actual definition of 3D bioprinting is still evolving. In essence, 3D bioprinting works similarly to FDM 3D printing and is in the material extrusion family, although extrusion isn’t the only bioprinting method.

3D bioprinting uses materials discharged from a needle to create layers. These materials, known as bioinks, are mainly composed of living matter, such as cells within a carrier material – like collagen, gelatin, hyaluronan, silk, alginate, or nanocellulose – that act as a molecular scaffold for the structure to grow and nutrients to provide support.

Construction 3D Printing

Construction 3D printing is a rapidly growing area of material extrusion. The technology involves using extremely large-scale 3D printers, often measuring tens of meters high, to extrude building material, such as concrete, from a nozzle. These machines generally come either as gantry or robotic arm systems.

3D construction printing technology is used today for homes, architectural features, and construction projects from wells to walls. Proponents say it has the potential to significantly disrupt the entire construction industry because it reduces the need for labor and cuts down on construction waste.

There are dozens of 3D-printed homes across the US and Europe, and research is underway to develop 3D construction technology that would use the materials found on the moon and Mars to build habitats for future expedition teams. Printing with local soil instead of concrete is also gaining attention as a more sustainable building method.

Resin 3D Printing

Vat polymerization (resin 3D printing) is a family of 3D printing processes that uses a light source to selectively cure (or harden) photopolymer resin in a vat. In other words, light is precisely directed to a specific point or area of the liquid plastic to make the material stiff. Once the first layer is cured, the build platform is moved up or down (depending on the printer).

The next layer is cured using a small amount (typically between 0.01 and 0.05 mm), joining the previous one. This process is repeated layer by layer until the 3D part is formed. After the 3D printing process, the object is cleaned to remove the remaining liquid resin and post-cured (either in sunlight or a UV chamber) to enhance the part’s mechanical properties.

The three most common forms of vat polymerization are stereolithography (SLA), digital light processing (DLP), and liquid crystal display (LCD) also known as masked stereolithography (MSLA). The fundamental difference between these types of 3D printing technology is the light source and how it is used to cure the resin. But there are still more 3D Printing technologies;

The other methods include:

- Material Jetting (M-Jet)

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Liquid Crystal Display (LCD)

- Powder Bed Fusion (PBF)

- Selective Laser Sintering (SLS)

- Laser Powder Bed Fusion (LPBF)

- Electron Beam Melting (EBM)

- NanoParticle Jetting (NPJ)

- Plastic Binder Jetting

- Sand Binder Jetting

- Multi Jet Fusion (MJF)

- Laser Directed Energy Deposition

- Electron Beam Directed Energy Deposition

- Wire Directed Energy Deposition

- Molten Direct Energy Deposition

In addition, Binder Jetting can also be used to fabricate solid metal objects with complex geometries well beyond the capabilities of conventional manufacturing techniques. Metal binder jetting is a very appealing, lightweight technology for volume metal part production. Because binder jetting can print parts with complex pattern infills instead of being solid, the resulting pieces are dramatically lighter while being as strong. Binder jetting’s porosity feature can also achieve more delicate end parts for medical applications, such as implants.

The 3D Printing Pros:

- Bespoke, cost-effective creation of complex geometries:

This technology allows for the easy creation of customized geometric parts where added complexity comes at no extra cost. Sometimes, 3D printing is cheaper than subtractive production methods as no additional material is used. - Affordable start-up costs:

Since no molds are required, the costs associated with this manufacturing process are relatively low. The price of a part is directly related to the amount of material used, the time taken to build the region, and any post-processing that may be required. - Completely customizable:

Because the process is based upon computer-aided designs (CAD), any product alterations are easy to make without impacting the manufacturing cost. - Ideal for rapid prototyping:

Because the technology allows for small batches and in-house production, this process is ideal for prototyping, which means that products can be created faster than with more traditional manufacturing techniques and without the reliance on external supply chains. - Allows for the creation of parts with specific properties:

Although plastics and metals are the most common materials used in 3D printing, there is also scope for creating pieces from specially tailored materials with desired properties. So, for example, parts can be made with high heat resistance, water repellency, or higher strengths for specific applications.

The 3D Printing Cons:

- Increased cost at high volume:

Large production runs are more expensive with 3D printing as economies of scale do not impact this process as they do with other traditional methods. Estimates suggest that when comparing identical parts directly, 3D printing is less cost-effective than CNC machining or injection molding more than 100 units, provided the components can be manufactured by conventional means. - Limitations in accuracy:

The accuracy of a printed part depends on the type of machine and process used. Some desktop printers have lower tolerances than others, meaning the final features may slightly differ from the designs. While this can be fixed with post-processing, it must be considered that 3D-printed parts may not always be exact. - Post-processing requirements:

Most 3D-printed parts require some form of post-processing. This may be sanding or smoothing to create a required finish, the removal of support struts that allow the materials to be built into the designated shape, heat treatment to achieve specific material properties or final machining.

3D Printing can also have lower strength than traditional manufacturing. While some parts, such as metal ones, have excellent mechanical properties, many other 3D-printed parts are more brittle than those created by conventional manufacturing techniques. This is because the components are built up layer-by-layer, which reduces the strength by between 10 and 50%.

In Conclusion;

Cold Spray is a DED 3D printing technology that sprays metal powders at supersonic speeds to bond them without melting them, which produces almost no thermal stress that can produce hot-cracking or other common problems that can affect melt-based technologies. Since the early 2000s, it’s been used as a coating process. Still, several companies are adapting it.

In particular, for additive manufacturing because it can layer metal in exact geometries up to several centimeters at about 50 to 100 times higher speed than typical metal 3D printers. There’s no need for inert gases or vacuum chambers. Like all DED processes, the cold spray doesn’t produce prints of excellent surface quality or detail, but that’s not always required.

The parts can be used right off of the print bed. Still, laminating is a 3D printing technology where sheets of material are layered on top of each other and bonded together using glue; then, a knife (or laser, or CNC router) is used to cut the layered object into the correct shape. The technology is less common today because other 3D printing technology costs have fallen.

In contrast, the size, speed, and ease of use of 3D printers in other technology categories have dramatically increased. Of course, our guide does not cover every take on the major categories of 3D printing; there are just too many, with new ones debuting all the time. Are they genuinely new technologies or proprietary enhancements of an established technology?